Why the nVent LENTON Swaged Terminator?

nVent LENTON is constantly innovating and engineering products for every project. For many years, hooked rebar anchorages have been the industry standard despite issues with congestion, intense labor requirements, and safety hazards. Our talented team has worked to develop a solution to code changes requiring increased rebar while maintaining a compact design.

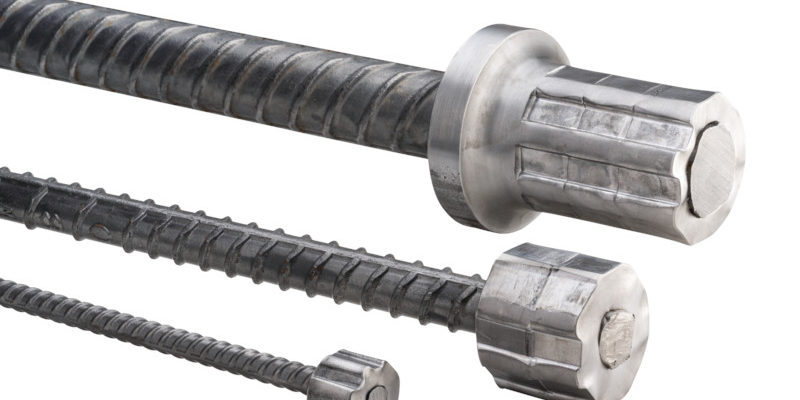

The nVent LENTON Swaged Terminator shakes up the current world of rebar with a simplified and more flexible design. High-speed, cold forging technology quickly attaches the Terminator to the reinforcing steel bar, allowing the front face to carry the full tension load of the rebar. With faster installation time and lower costs, headed rebar anchorages are the alternative for hooked rebar you’ve been looking for.

Want to know more? |

Look at the product pages to learn about all the benefits and applications of the nVent LENTON Swaged Terminator.Read On |

Product Benefits

The benefits of the Terminator show a stark contrast between headed and hooked rebar. With extra levels of reliability and economic savings, our Swaged Terminator can bring your next job site into the future of rebar. While hooked rebar requires longer development lengths—which causes congestion and restricts the flow of larger aggregates—the nVent LENTON Swaged Terminator simplifies rebar placement by eliminating the rebar hook entirely. Enjoy a faster installation process with minimal detailing required, and many more advantages.

Product Performance and Evaluation Report

- Designed to meet Caltrans Ultimate performance with A706 grade 60 rebar, ASTM A970 Classes A, HA, and B performance with A706 and A615 grade 60 and grade 80 rebar

- IAPMO UES Evaluation Report: IAPMO ® -UES ER-0188

Other Benefits

The Terminator is available in two diameters to help you accomplish your job-site goals: the DT14 whose head area exceeds 10x (net 9x) bar area, and the DT16 whose head area exceeds 5x (net 4x) bar area. In addition to multiple diameters, multiple safety features are available with the Swaged Terminator’s non-stick and lightweight tooling. Operator training takes only a few minutes to complete and then you’re ready to begin your project.

Have additional questions? Contact your local nVent sales representative today.